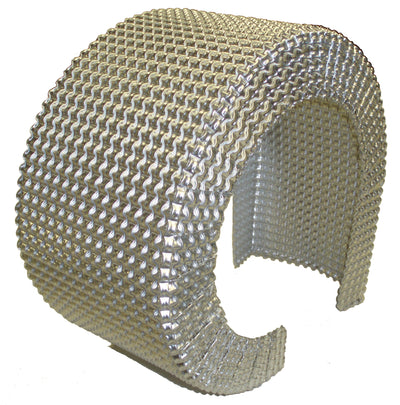

Nimbus G2 – Dual layer aluminium heat shield

Nimbus G2 is a dual layer aluminium heat shield material offering a solution to heat and weight reduction problems commonly faced in the automotive industry. This versatile, lightweight heat shield is both highly thermally efficient and highly formable allowing it to be used in many applications even where space is a premium. The material can be formed into very complex shapes, making this a favourite amongst tier 1 and tier 2 manufacturers supplying the automotive industry.

Nimbus G2 has a unique construction using two thin interlocking corrugated aluminium sheets. These sheets form a product that is highly formable but also rigid in structure. As the two layers are embossed together an insulating air pocket is created within the product which increases the high thermal performance of the aluminium, this results in a 15-30% improvement compared with typical sandwich-style heat shield construction.

The corrugation of the Nimbus G2 allows for high formability, the material can be stretched without tearing and compressed without warping. This means that the material can be used to form large/complex heat shields from one piece of material where traditional shields would have previously enforced the use of multiple pieces due to the limitations of the material.

The choice of 1050A ‘O’ grade aluminium used in production of the Nimbus G2 offers a few noteworthy benefits compared with the more traditional steel based heat shields. Weight is a major factor with the G2 showing a saving of approximately 80% with no reduction in performance, this weight saving is valuable for motorsport applications where every ounce counts and road applications where weight saving is valuable in the quest for economy and lower emissions.

Aluminium is also inherently resistant to corrosion which dramatically improves the lifespan of the product without the need for any costly additional coatings, steel based heat shields have a tendency to rust and weaken around fixings which leads to them becoming loose and eventually failing. Unlike many steel heat shields the G2 does not rely on any additional fillers within the product to aid performance, this makes the material 100% recyclable.

To summarise the benefits, Nimbus G2 is a lightweight, highly thermally efficient heat barrier which may be easily formed into complex shapes to fit into tight areas in and around the engine bay.

Nimbus G2 dual layer aluminium heat shield specification

Nimbus G2 is double formed using two layers of 1050A ‘O’ grade aluminium, one measuring 0.36mm thick and the second a lighter weight at 0.15mm. These are double formed using a two stage process which locks the layers together while also creating pockets of air which aid the performance of the material. The final product measures 4.45mm in thickness.

Applications for dual layer aluminium heat shield

While the Nimbus G2 is predominantly used for automotive applications, the performance and benefits of the material also make it ideal for any application where radiant heat poses a risk of damage. We have experience supplying Nimbus G2 into a wide range of commercial applications, examples include but are not limited to industrial generators, power stations, marine, plant machinery, aircraft and refrigeration. We have also seen people use Nimbus G2 to form an effective wood stove heat shield.

How to use aluminium heat shield

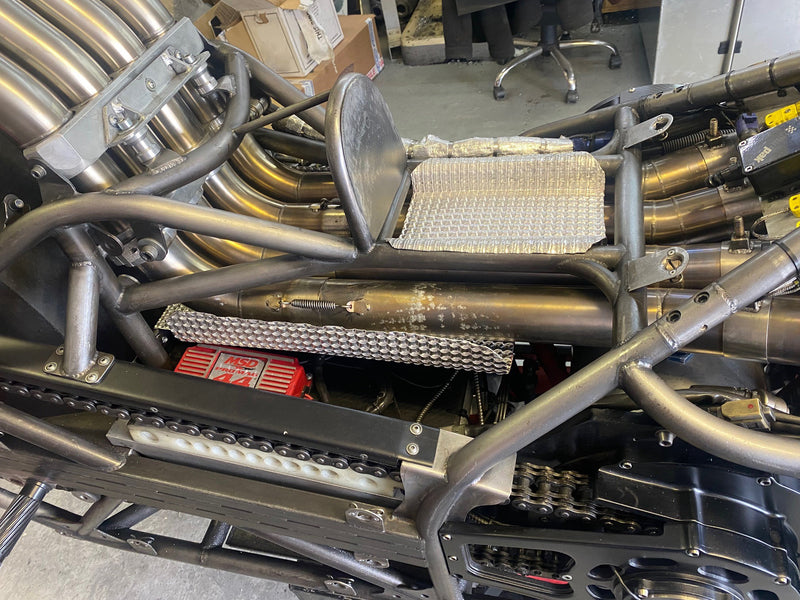

The Nimbus G2 is easily formed and can be manipulated into shape using a variety of methods, molds and presses may be used for larger scale production runs but for bespoke one-offs it is easy to make an effective heat shield with very limited tools. The example above started as a flat sheet of G2, this was cut using tin snips then given its strength with pop rivets on the joins. This method allows you to fabricate a shield with complex shapes and curves to fit within the tight confines of your engine bay.

Exhaust heat shield

A common application for the Nimbus G2 Heat Shield is for the fabrication of exhaust heat shields. Exhaust systems can get incredibly hot and often run close to other engine components and bodywork which can be damaged and compromised by heat. Nimbus G2 can be formed into very complex shapes allowing it to be used in tight spaces where space is a premium.

We are fortunate to work with some fantastic people in our industry, local to us is Charles of CSK Exhausts, a talented fabricator specialising in custom exhaust systems. He recently used the Nimbus G2 to form an exhaust heat shield which he positioned above the exhaust system to reflect heat and reduce under bonnet temperatures. This is an excellent example of how the Nimbus G2 heat shield can be used for any exhaust system.

Custom size aluminium heat shield

From the factory our sheets of Nimbus G2 heat shield measure 1230mm x 1200mm (G2A), we cut these sheets into half (1200mm x 615mm G2B) and half again (600mm x 615 G2C), these are the 3 standard sizes available.

All cutting takes place in our UK warehouse and is done on our Morgan Rushworth guillotine, this industry leading machine allows us to cut large quantities of material quickly with no compromise on quality. Every sheet that leaves our premises in handled individually and passes our thorough levels of quality control.

Having full control over the cutting we have the ability to offer custom sizes, for more details please contact our office and we will be very happy to arrange a quotation for this service.

Supplying tier 1 and tier 2 manufacturers we understand the importance of reliable supply of materials, every effort has been made to maintain excellent stock which allows us to meet production schedules for our customers without any delays. This emphasis on stock also ensures we can quickly despatch one off orders for end users, most orders received before 12 noon are despatched the same day and can be with you the following day.

Thanks for reading this guide, for more information on other areas that can benefit from heat shielding please check out our introduction to heat management.